PRODUCTS

Company: Shenzhen Rev Laser Equipment Co., Ltd

Website: www.revlaser.com. cn

Address: 2nd Floor, Building A, Tongfuhan Haida Innovation Park, No. 10 Jiangfu Road, Matian Street, Guangming District, Shenzhen

Mobile: +86-15889513597

Email: revlaser@163.com

Laser Repair Machines

HomeLaser Repair MachinesDetails

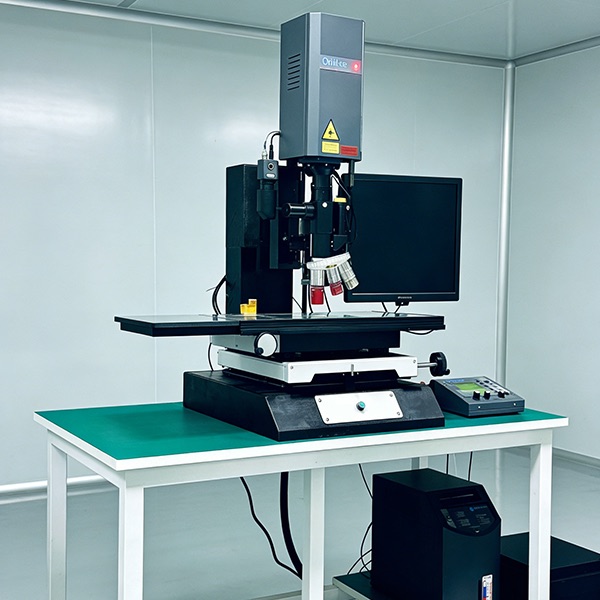

LCD-OLED Panel Laser Repair Machine REV-310-SD

Equipment introduction:

Laser repair machine is a laser repair system designed for TFT-LCD display panels. The equipment is equipped with (New wave) REV-3018 series laser systems (including Laser Head and Laser Power), precision optical imaging systems (laser processing/observation microscope, laser processing special optical objective lens, image observation objective lens), X/Y/Z three-axis manual displacement focusing system, precision marble platform base + simple open work stage. This equipment can repair defects such as short circuits for specific material layers of workpieces. The processed parts are picked and placed in manual mode.

Basic information

product model | REV-310-SD | working environment | open |

power demand | 220V,50~60Hz | control methods | manually |

Product size | 1200mm x 700mm x 1800mm | equipment weight | Approximately 300KG |

Technical characteristics and advantages

● High-end core configuration is supported, leading the industry in repair stability ● Multi-dimensional and precise control to adapt to complex repair scenarios ● Comprehensive optical imaging system for more accurate defect identification and repair ● Strong flexible adaptation capabilities covering multi-specification panel requirements ● Software functions More suitable for industrial-level operation needs ● The balance of customization and compatibility is more advantageous

1. Machine specifications

| X/Y/Z axis drive system | |

| project | description |

| Effective travel in X, Y, and Z axes | 200mm x 100mm (XY stage glass can be enlarged) |

| X and Y axis drive form | 1um/pulse (manual adjustment of displacement) |

| reproducibility | 100mm |

| Z-axis drive form | Precision screw (electric adjustment displacement focus) |

| Z-axis minimum resolution | 0.1um/pulse |

| (Subject to the actual design configuration) | |

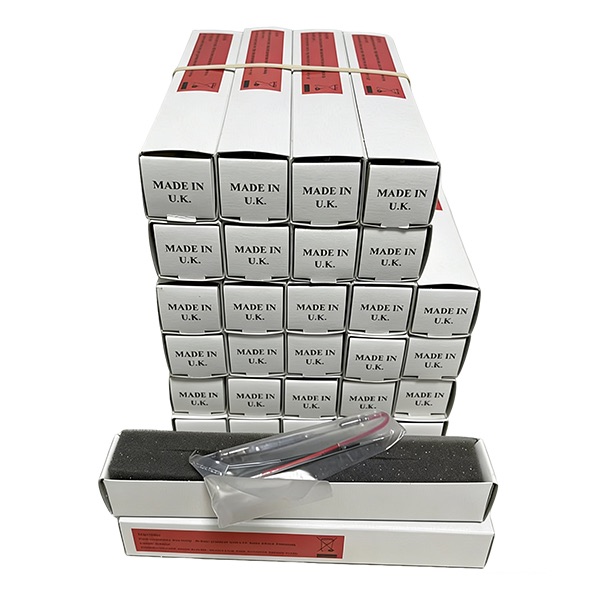

2. Laser system

2-1 You can choose New Wave, REV-3018 and other series laser systems, according to the cutting material configuration requirements.

(Subject to the actual laser configuration).

| 2-2 Laser Slit | |

| project | description |

Repair size | Lens magnification processing size |

| NIR 50x objective; min: 3um x 3 um | |

| NIR 20x objective lens max: 120um x 120um | |

| 2-3 optical image system | |

| project | description |

| microscope | Observation/laser processing special type |

| CCD | 1/2”Color CCD |

| epi-light source | High-brightness LED point light source |

| transmission light source | backlight |

| Guide Light | LED(Blue) |

| objective lens switching system | 4 holes/manual switching type |

| 2-4 Precision objective lens group | |

| project | description |

| M Plan APO 5 x | observation |

| M Plan APO 10 x | observation |

| M Plan NIR 20 x | Observation/laser processing |

| M Plan NIR 50 x | Observation/laser processing |

| 2-5 autofocus system | |

| project | description |

| Focus type | Manual focusing |

| 2-6 processing stage | |

| project | description |

| main function | Workpiece carrying use |

| material | Precision Grinding Optical Glass Stage |

| size | 708.4mm x 398.5mm(customizable) |

| base table | Precision marble |

| 2-7 suspension system | |

| project | description |

| Shock absorber form | Shock absorber form |

| Natural frequency (vertical/horizontal) | 2~2.3 Hz |

| Manufacturer gas supply specifications | 4~6 kg/㎠ (Compressed or Nitrogen Gas) |

| (Equipment requirements floor shockproof level: Level B) | |

| 2-9 other specifications | |

| project | description |

| backlight box | Looking for highlights and defects of light source light box |

3. Operation mode

3-1 Software features no

(1) Laser control box

(2)Laser manual operation firing function (foot pedal).

(3)Manual XYZ three-axis displacement focus, and the screen cursor moves.

(4)The matching settings of standard parameters of the control box are adjustable.

(5)The control box knob turns on the Slit function. The cursor movement on the screen corresponds to the adjustment of Slit size.

(6)User login/login key power switch.

(7)Manual adjustment of upper and lower light sources.

(8)The upper and lower light sources are adjusted manually in conjunction with each magnification setting.

(9)Lens switching manual correction function.

(10)Operate the English menu.

3-2 In manual operation mode, the operator can manually adjust and move XYZ and confirm it through the system screen.

4. Public equipment

| 4-1 power supply | |

| project | description |

| number of groups | 1 group |

| power supply | 2 phase /AC 220 V ± 10%, 30A |

| power connector | M6 terminal block |

| ground line | JIS level 1,8 mmsq or above |

5. appearance

| project | description |

| number of groups | 2 groups |

| size | Within 1200mm(W) x 700mm(D) x 1800mm(H) |

| weight | Within 300KG |

| (Based on the actual design size) | |

6. use environment

| temperature | 20℃±5℃ |

| humidity | 30~60 (no dew condensation state) |

| dust | It is recommended for use in clean rooms above level 10000. The laser is a combination of optical parts and therefore is used in an environment with less dust. |